VW55 vibration friction welding machine suppliers

Category:

Vibration Friction Welding Machine

Description:

Hydraulic clamp by the oil tank, power agencies, directional valves, pressure relief valve, pumping institutions, pumping institutions by the oil pump body

In the world of manufacturing, a remarkable innovation has emerged - the Vibration Friction Welding Machine. And now, there are exciting opportunities for businesses to avail themselves of these machines.Wholesale options are available, allowing companies to purchase in bulk at discounted prices. Buyers can find high-quality Vibration Friction Welding Machines from trusted manufacturers and factories. These machines are known for their Best quality and can also be Customized to meet specific requirements.

Key words:

Industrial switches

VW55 vibration friction welding machine suppliers

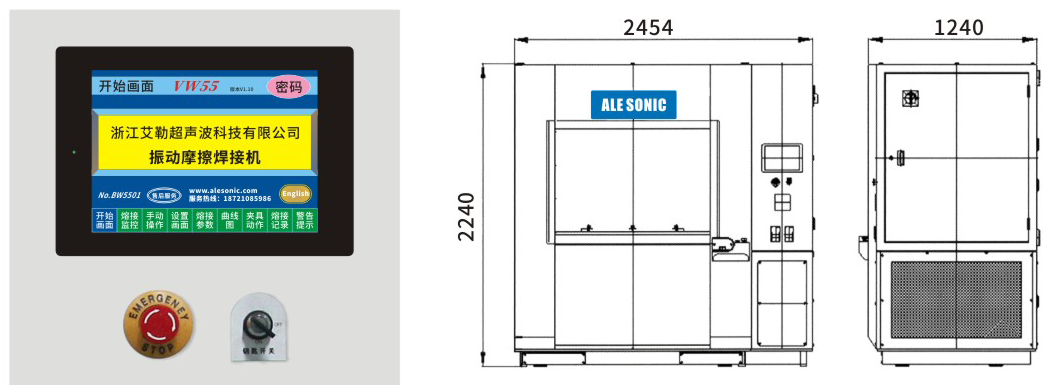

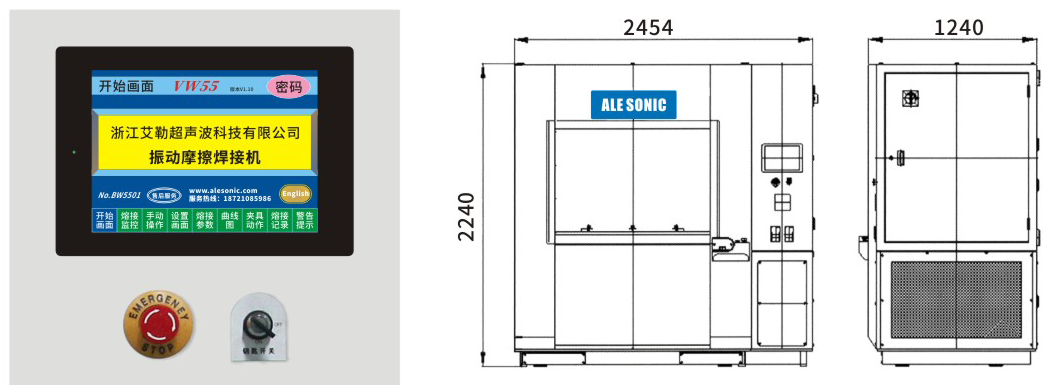

VW55 linear vibration friction welding machine is a plastic welding equipment specially used for welding large or irregular shaped thermoplastic workpieces. The equipment can weld large irregular plastic workpieces up to 280cm ² and a variety of smaller plastic workpieces. VW55 is equipped with digital vibration variable frequency power source, with automatic resonance and frequency automatic tracking adjustment frequency function. This machine uses easy to operate touch screen control display and professional control software. High welding strength, good quality, used in large auto parts, plastic products, home appliances, office automation parts industry.

In the world of manufacturing, a remarkable innovation has emerged - the Vibration Friction Welding Machine. And now, there are exciting opportunities for businesses to avail themselves of these machines.Wholesale options are available, allowing companies to purchase in bulk at discounted prices. Buyers can find high-quality Vibration Friction Welding Machines from trusted manufacturers and factories. These machines are known for their Best quality and can also be Customized to meet specific requirements.

There are Cheap and even Cheapest alternatives for those looking to save costs without compromising on performance. Suppliers(s) in China are offering these machines at Low prices, ensuring good price and quality.

The products are on sale, and you can find them in various locations in China. Whether you're looking for a local supplier near you or prefer to source from Manufacturers china, there are plenty of choices. The price(s) china are highly competitive, making it an attractive option for businesses.

Companies are committed to providing these machines at Wholesale Price, and with the focus on quality materials, they ensure durability and reliability. From China manufacturer, these Vibration Friction Welding Machines are set to transform the industrial landscape.

So, if you're in the market for a reliable and efficient Vibration Friction Welding Machine, look no further. Explore the options available and take advantage of the great deals on offer. It's a new era for manufacturing with these cutting-edge machines.

Features & Benefits

● Use high frequency, high friction effect

● Use IGBT mode AMPA

● Use of ASIC power stations

● Automatically keep the amplitude constant

● Controllable output power

● Welding mode setting: depth, time

● Automatic resonance function

● Welding result judgment function

● Multi-stage welding

● Easy-to-operate touch display

● Multi-language interface

● Storage operating conditions

● Convenient replacement of fixtures

● Equipped with sound insulation device

Performance parameters

| Overall size | 1240mm wide 2454mm long 2240mm high |

| Weight of upper die | 5~55Kg |

| Welding area | 280cm |

| amplitude | 0.7-1.8mm |

| vibration frequency | 220-260HZ |

| Load vibration output | 18.5KW |

| Voltage | AC380V,3-phase |

| Input capacity | 29KVA |

| System Control | PLC Mitsubishi FX3U |

| Touch screen | Mitsubishi GT11 Series |

| Welding method | Time Mode Depth Mode |

| Save Results | 100 one |

| welding result analysis | Qualified Unqualified |

| multi-stage pressure control | |

| Ambient temperature | 0-50℃ |

| Table stroke | 500mm |

| Table moving speed | 250 mm/s (max) |

| Table Pressure | 50-1800kg |

| Safety door opening space | Width 1400mm Height 790mm |

| switchboard weight | 4100kg |

Applicable Product Application

VW55 linear vibration friction welding machine is a plastic welding equipment specially used for welding large or irregular shaped thermoplastic workpieces. The equipment can weld large irregular plastic workpieces up to 280cm ² and a variety of smaller plastic workpieces. VW55 is equipped with digital vibration variable frequency power source, with automatic resonance and frequency automatic tracking adjustment frequency function. This machine uses easy to operate touch screen control display and professional control software. High welding strength, good quality, used in large auto parts, plastic products, home appliances, office automation parts industry.

In the world of manufacturing, a remarkable innovation has emerged - the Vibration Friction Welding Machine. And now, there are exciting opportunities for businesses to avail themselves of these machines.Wholesale options are available, allowing companies to purchase in bulk at discounted prices. Buyers can find high-quality Vibration Friction Welding Machines from trusted manufacturers and factories. These machines are known for their Best quality and can also be Customized to meet specific requirements.

There are Cheap and even Cheapest alternatives for those looking to save costs without compromising on performance. Suppliers(s) in China are offering these machines at Low prices, ensuring good price and quality.

The products are on sale, and you can find them in various locations in China. Whether you're looking for a local supplier near you or prefer to source from Manufacturers china, there are plenty of choices. The price(s) china are highly competitive, making it an attractive option for businesses.

Companies are committed to providing these machines at Wholesale Price, and with the focus on quality materials, they ensure durability and reliability. From China manufacturer, these Vibration Friction Welding Machines are set to transform the industrial landscape.

So, if you're in the market for a reliable and efficient Vibration Friction Welding Machine, look no further. Explore the options available and take advantage of the great deals on offer. It's a new era for manufacturing with these cutting-edge machines.

Features & Benefits

● Use high frequency, high friction effect

● Use IGBT mode AMPA

● Use of ASIC power stations

● Automatically keep the amplitude constant

● Controllable output power

● Welding mode setting: depth, time

● Automatic resonance function

● Welding result judgment function

● Multi-stage welding

● Easy-to-operate touch display

● Multi-language interface

● Storage operating conditions

● Convenient replacement of fixtures

● Equipped with sound insulation device

Performance parameters

| Overall size | 1240mm wide 2454mm long 2240mm high |

| Weight of upper die | 5~55Kg |

| Welding area | 280cm |

| amplitude | 0.7-1.8mm |

| vibration frequency | 220-260HZ |

| Load vibration output | 18.5KW |

| Voltage | AC380V,3-phase |

| Input capacity | 29KVA |

| System Control | PLC Mitsubishi FX3U |

| Touch screen | Mitsubishi GT11 Series |

| Welding method | Time Mode Depth Mode |

| Save Results | 100 one |

| welding result analysis | Qualified Unqualified |

| multi-stage pressure control | |

| Ambient temperature | 0-50℃ |

| Table stroke | 500mm |

| Table moving speed | 250 mm/s (max) |

| Table Pressure | 50-1800kg |

| Safety door opening space | Width 1400mm Height 790mm |

| switchboard weight | 4100kg |

Applicable Product Application

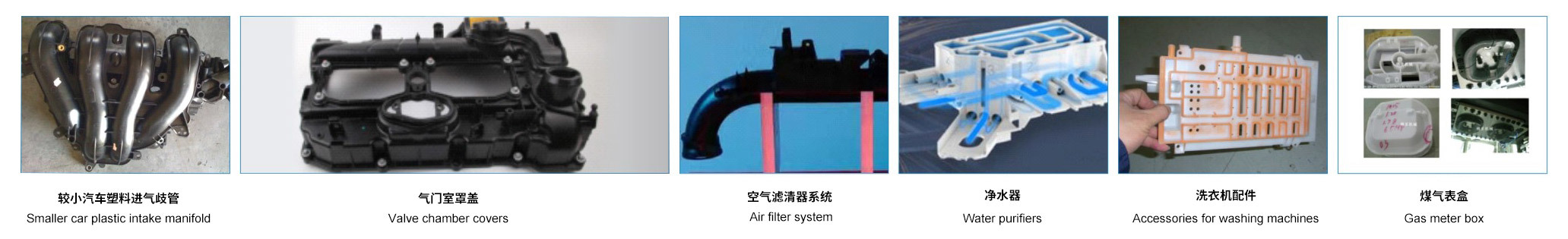

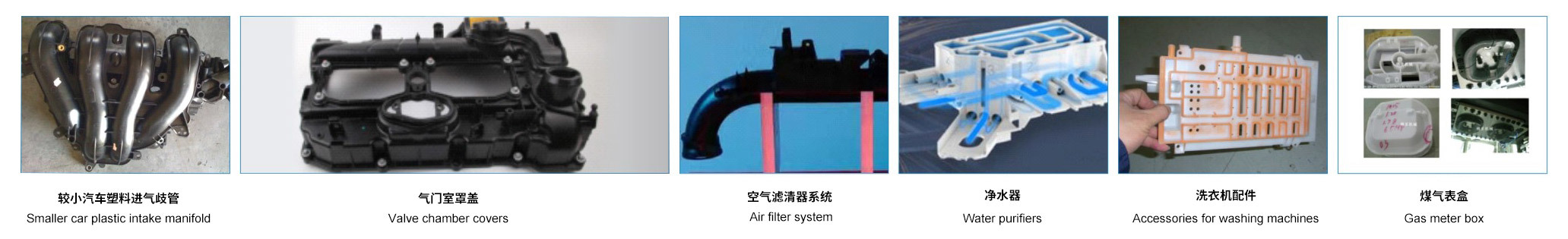

Vibratory friction welding machine in the automotive applications most notably embodied in the engine air intake system, interior and exterior trim parts and lights. Intake manifold are basically used are PA plus glass fibre reinforced materials, and in terms of the current process only vibration friction welding requirements can be achieved, whether it is from the airtight, burst pressure strength are other connections can not be achieved. In terms of lamps, most of the previous hot plate welding, and in recent years many manufacturers began to switch to vibration friction welding, mainly due to the vibration friction welding overflow is less (the appearance of the lamp is particularly important), welding cycle is short, greatly improving productivity, strength can also meet the requirements.

Previous page

Previous page

VW70 vibration friction welding machine For sale